|

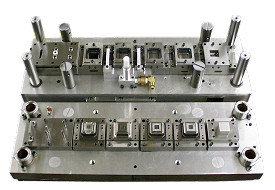

A significant factor in Valentine’s ability to provide world class metal stampings is as a result of our complete control over the in-house design and fabrication of all customer tooling. Having in-house tool build capability often puts Valentine at a competitive advantage over other stamping houses that rely on outside design and tool build firms where tooling lead times may be critical. Additional benefits are realized in the event that the customer has design upgrades that need to be implemented on existing production tooling. Changes can often be made much sooner than a competitor who may have to rely on a redesign by a third party tool design service. A significant factor in Valentine’s ability to provide world class metal stampings is as a result of our complete control over the in-house design and fabrication of all customer tooling. Having in-house tool build capability often puts Valentine at a competitive advantage over other stamping houses that rely on outside design and tool build firms where tooling lead times may be critical. Additional benefits are realized in the event that the customer has design upgrades that need to be implemented on existing production tooling. Changes can often be made much sooner than a competitor who may have to rely on a redesign by a third party tool design service.

Valentine has a fully equipped tool room capable of supporting any customer tool build requirement. Key equipment includes milling, grinding, jig boring, jig grinding, sinker EDM, and wire EDM machinery. More importantly, Valentine’s staff of skilled craftsman are well trained in progressive tool build and maintenance procedures and possess the analytical skills necessary to support the complex tooling needed to produce components to the level of quality demanded by our customers. Valentine has a fully equipped tool room capable of supporting any customer tool build requirement. Key equipment includes milling, grinding, jig boring, jig grinding, sinker EDM, and wire EDM machinery. More importantly, Valentine’s staff of skilled craftsman are well trained in progressive tool build and maintenance procedures and possess the analytical skills necessary to support the complex tooling needed to produce components to the level of quality demanded by our customers.

|